TABLE 161 General Characteristics of Sheet-metal Forming Processes in alphabetic order a Schematic illustration of shearing with a punch and die indicating some of the process variables. A part with a given quality.

Sheet Metal Forming Sheet Metal Sheet Metal Tools Sheet Metal Roller

Sheet Metal Forming Sheet Metal Sheet Metal Tools Sheet Metal Roller

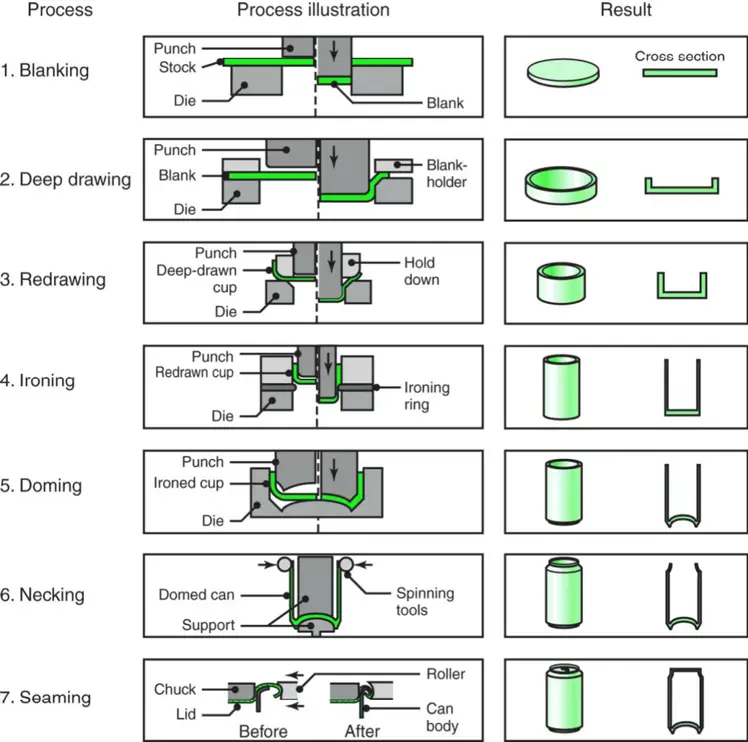

The schemes of the metal forming processes.

General characteristics of sheet metal forming processes in alphabetic order. The process is Typically ironing should not exceed a depth of 30 of the material thickness. Pressworking or press forming because sheet metal operations performed using presses using a set of dies stamping square4 Thickness of sheet metal 04 mm 164 in to 6 mm 14 in square4 Thickness of plate stock 6 mm. Another common sheet metal forming process is bending.

Forming Process also known as Metal Forming is a large set of the manufacturing process by which a raw material converted into a product. The example of forming processes are sheet metal manufacturing forging rolling extrusion wire drawing thread rolling rotary swinging and so on. TABLE 161 General Characteristics of Sheet-metal Forming Processes in alphabetic order FIGURE 162 a Schematic illustration of shearing with a punch and die indicating some of the process variables.

Large sheets with relatively simple shapes low tooling cost but high labor cost low-quantity production long cycle times. Bulk deformation processes and sheet metal working processes. In this process we apply stresses like tension compression shear etc.

B cross rolling. For almost all sheet metal components blankingpunching or cutting off is the very first process. Order to obtained the desired result.

Suitabl e for low-quan tity production. Metal forming is one of the important manufacturing processes. By doing so the sheet can be bent or stretched into a variety of complex shapes.

The plastic deformation is most commonly large. The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail. There are three types of metal forming processes.

Little or no material is removed during the forming process. A portion of the part is reduced in diameter to less than the major diameter. Square4 Numerous processes for making sheet-metal parts square4 Terms used in industry.

Sheet metal often contains sharp edges with burrs after its initially produced. The workpiece is completely or partially subjected to plastic deformation during the forming operation. Metal forming processes can be classified under two major groups.

In sheet metal working the metal being processed will have a high surface area to volume ratio. Rib forming involves creating an inward or outward protruding rib during the drawing process. Here is a list of sheet metal forming processes- 1.

Cutting Off Blanking Punching and Piercing Processes. On the industrial scale forming is characterized by2 Very high loads and stressesrequired between 50 and 2500 Nmm27-360 ksi Large heavy and expensive machinery in order to accommodate such high stresses and loads. Bulk deformation is characteristic in that the work formed has a low surface area to volume ratio.

Cutting Off Blanking Punching and Piercing Process 2. Companies typically perform bending on sheet metal using either a brake press or similar machine press. Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes cuttingand joining.

Stretch form-ing Large parts with shallow contours. Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material. High production rates high tooling and equipment costs.

Curling is a forming process that involves de-burring sheet metal to produce smooth edges. Sheet-Metal Forming Processes TABLE 71 General characteristics of sheet-metal forming processes. Pr ocess Characteristics Roll forming Long parts with constant complex cross-sections.

This process is typically used to put. Shallow or deep parts with relatively simple shapes high production rates high toolling and equipment costs. That is it is plasticized.

Therefore it will be important to have a design that. Good surface Þni sh. Uday Shanker Dixit in Mechanics of Materials in Modern Manufacturing Methods and Processing Techniques 2020.

A lengthwise rolling. The products and components created by the different metal shaping techniques are used in creating everything from scaffolding and heavy machinery to designing and creating microprocessors and artificial intelligence. C helical roll- ing 1 2 rolls.

Bulk metal forming sheet metal forming and sheet-bulk metal forming. Introduction to sheet metal forming processes. So that its characteristics are rather a factor of noise than a useful information.

Metal forming processes are an essential part of our society and without them our society would come to a grinding halt. To deformed the raw material. 13 Characteristics of Metal Forming Following are some general characteristics of metal forming processes.

General Characteristics of Sheet-Metai Forming Processes in alphabetic order Forming process Drawing Explosive Magnetic-pulse Roll Rubber Spinning Stamping Stretch Superplastic Characteristics Shallow or deep pans with relatively simple shapes.

Add Flat Pattern In Sheet Metal Drawings Creo Parametric 5 0 Youtube

Add Flat Pattern In Sheet Metal Drawings Creo Parametric 5 0 Youtube

Press Brake Allowance Chart Allowance Chart Press Brake Sheet Metal Fabrication

Press Brake Allowance Chart Allowance Chart Press Brake Sheet Metal Fabrication

How To Form Copper Bowls From Sheet Metal By Hand Copper Bowl Sheet Metal Copper

How To Form Copper Bowls From Sheet Metal By Hand Copper Bowl Sheet Metal Copper

Https Link Springer Com Content Pdf 10 1007 2f978 3 642 58857 0 4 Pdf

Sheet Metal Tool Box Plans Quotes Metal Tool Box Sheet Metal Tools Tool Box

Sheet Metal Tool Box Plans Quotes Metal Tool Box Sheet Metal Tools Tool Box

Tom S Techniques Reference Reference Reference Chart Techniques

Tom S Techniques Reference Reference Reference Chart Techniques

Hand Forming Sheet Metal Techniques Sheet Metal Metal Shaping Metal Fab

Hand Forming Sheet Metal Techniques Sheet Metal Metal Shaping Metal Fab

Special Forming Tooling Metal Working Sheet Metal Fabrication Metal Working Tools

Special Forming Tooling Metal Working Sheet Metal Fabrication Metal Working Tools

Shaping Operations Are Generally Divided Into Three Groups Based Upon How The Parent Metal Flows Or Deforms During The Shaping Process Namely Bending Ppt Download

Shaping Operations Are Generally Divided Into Three Groups Based Upon How The Parent Metal Flows Or Deforms During The Shaping Process Namely Bending Ppt Download

Sheet Metal Drawing Sheet Sheet Metal Sheet Metal Drawing Drawing Sheet

Sheet Metal Drawing Sheet Sheet Metal Sheet Metal Drawing Drawing Sheet

Sheet Metal Forming Processes And Equipment Machinemfg

Sheet Metal Forming Processes And Equipment Machinemfg

Metal Forming Glossary B From Advantage Fabricated Metals

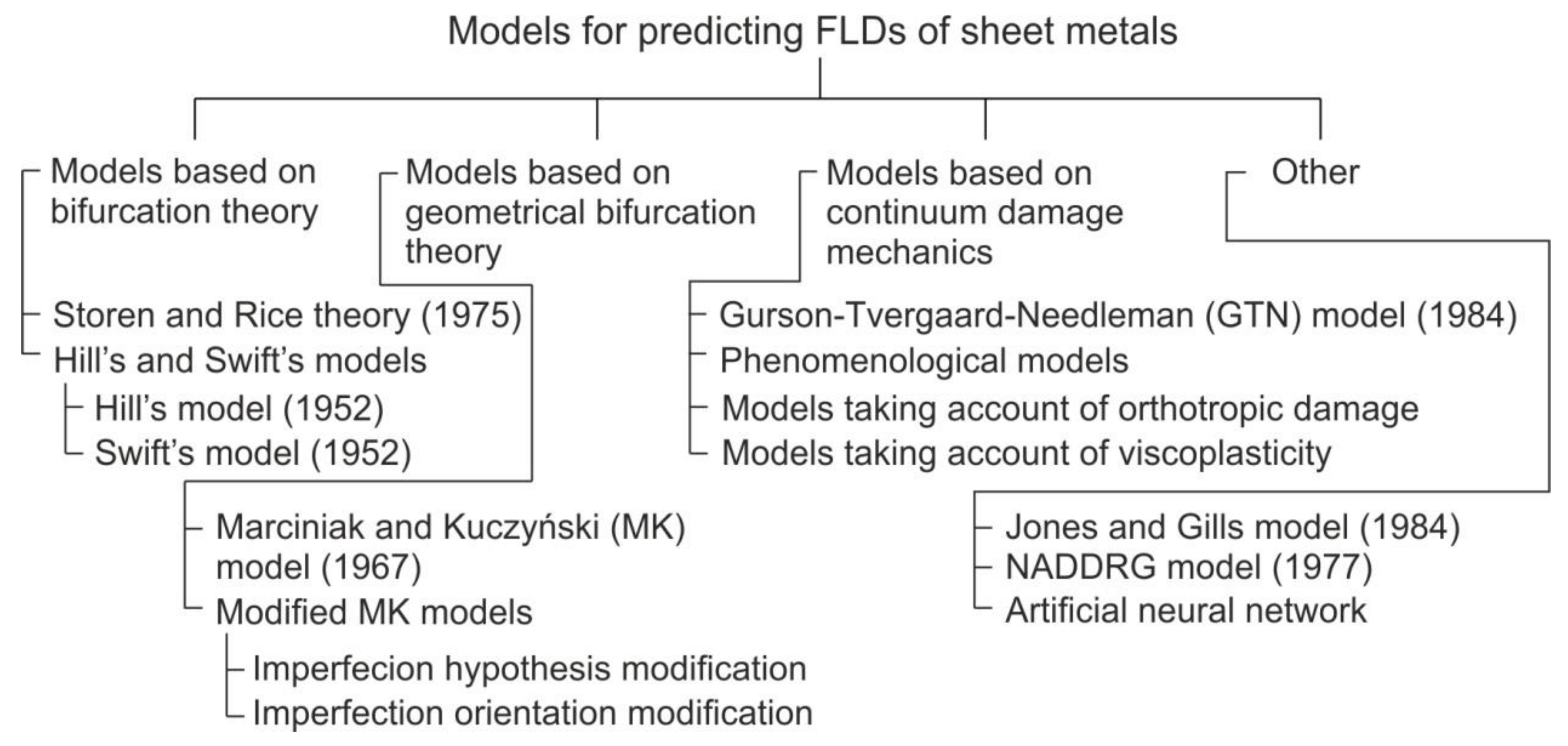

Metals Free Full Text Recent Developments And Trends In Sheet Metal Forming Html

Metals Free Full Text Recent Developments And Trends In Sheet Metal Forming Html

Tolerance Image Sheet Metal Fabrication Sheet Metal Metal Fabrication

Tolerance Image Sheet Metal Fabrication Sheet Metal Metal Fabrication

Fabrication Of Edges Joints Seams And Notches Sheet Metal Work Sheet Metal Fabrication Sheet Metal

Fabrication Of Edges Joints Seams And Notches Sheet Metal Work Sheet Metal Fabrication Sheet Metal

Metal Sheet Technique The Complete Solution Machinemfg

Metal Sheet Technique The Complete Solution Machinemfg

Pdf Recent Developments And Trends In Sheet Metal Forming

Pdf Recent Developments And Trends In Sheet Metal Forming

Http Www Uoh Edu Sa Facultymembers En B Ayadi Publishingimages Pages Teaching Activity Ch16 20 20sheet Metal 20forming Pdf

Unit 4 Sheet Metal Process Ppt Cheat Sheets Sheet Solutions

Unit 4 Sheet Metal Process Ppt Cheat Sheets Sheet Solutions

Post a Comment

Post a Comment